Il trasmettitore di pressione a film piatto LEFOO LFT2700 adotta il sensore a membrana a filo 316L, che è anti-intasamento, facile da pulire, può misurare direttamente la pressione del liquido viscoso, ecc., E ha eccellenti prestazioni anticorrosione e antiusura.Sensore di pressione piattaAdotta la tecnologia ASIC, la compensazione digitale, la connessione filettata, l'installazione e la manutenzione facili. L'interfaccia filettata è opzionale, la struttura esterna è piccola e una varietà di metodi di connessione dell'uscita elettrica sono opzionali. I sensori filettati a membrana piatta in silicone a diffusione per applicazioni di manometro o pressione assoluta possono misurare direttamente i media viscosi come rivestimenti chimici, vernici, petrolio greggio, ecc. È ampiamente utilizzato nell'industria chimica, nel sistema di rilevamento della vernice, nella protezione dell'ambiente, nella miniera di carbone, nella fabbricazione della carta, nella lavorazione degli alimenti, nelle attrezzature in poliuretano.

Lefoo sensore di pressione a Film piatto di tipo generale LFT2700 Feature

* Utilizzo del sensore a membrana a filo 316L, anti-intasamento, facile da pulire

* Può misurare direttamente la pressione dei liquidi viscosi

* Adotta la tecnologia ASIC, la tecnologia di compensazione digitale

* Eccellente resistenza alla corrosione e all'usura

* Connessione filettata per una facile installazione

| LEFOO General Type Flat Film Pressure Transducer LFT2700 | |||||

| Measurement Range | -100Kpa…0~20KPa…35MPa | ||||

| Overload Pressure | 1.5 time of full scales | ||||

| Accuracy | ±0.5%F.S.,±1.0%F.S. | ||||

| Stability | <0.5%F.S./Year | ||||

| Working Temperature | -20~+85℃ | ||||

| Storage Temperature | -40~+100℃ | ||||

| Measured Medium | All corrosive mediums can be compatible with 304/316 stainless steel, Fluoroelastomer or NBR. | ||||

| Electrical properties | Two-wired | Three-wired | Four-wired | ||

| Output Signal | 4~20mA | 0.5~4.5V | 0~5V | 0~10V | RS485 |

| Power Supply | 10~36VDC | 4.75~5.25VDC | 10~36VDC | 12~36VDC | 10~30VDC |

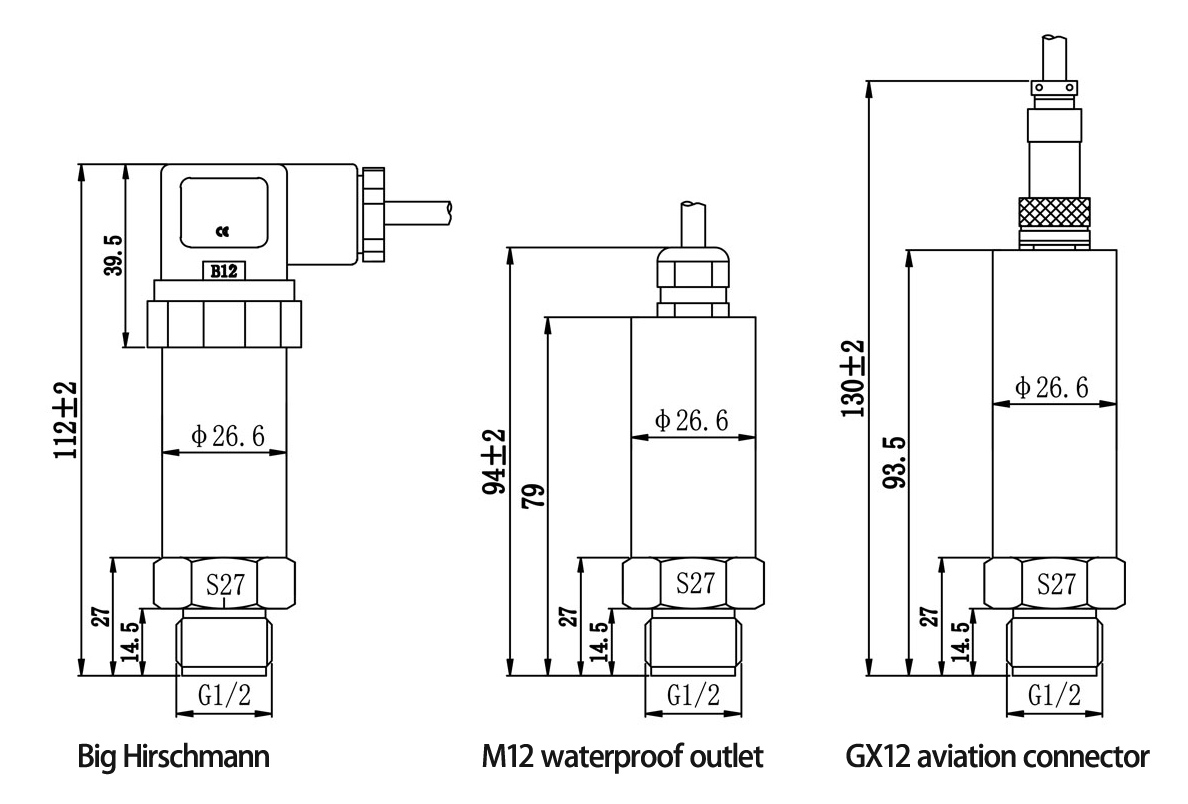

| Electrical Connection | DIN43650A (Big Hirschmann), M12 waterproof outlet, GX12 aviation connector (three cores/four cores) | ||||

| Protection Grade | IP65 / IP54 | ||||

| Pressure Connection | G1/2、M20*1.5 etc. | ||||

| Pressure Form | Gauge pressure G/ Absolute pressure A | ||||

| Certification | RoHS, EU electrical safety standard CE | ||||

| Code and Description | Remark | ||||||||||

LFT2700 | General Type Flat Film Pressure Transducer | Model | |||||||||

Range | -100Kpa…0~20KPa…35MPa | Measurement range | |||||||||

A4 | A4 = 4~20mA(Two-wired) | Output mode | |||||||||

V05 | V05 = 0.5~4.5V(Three-wired) | ||||||||||

V0 | V0 = 0~5V(Three-wired) | ||||||||||

V10 | V10 = 0~10V(Three-wired) | ||||||||||

RS | RS485 = RS485(Four-wired) | ||||||||||

K | K = kpa | Unit | |||||||||

| P | P = psi | ||||||||||

| B | B = bar | ||||||||||

M | M = Mpa | ||||||||||

0.5 | 0.5= ±0.5%F.S. | Accuracy | |||||||||

| 1.0 | 1.0= ±1.0%F.S | ||||||||||

D1 | D1 = DIN43650A Big Hirschmann | Electrical connection | |||||||||

M | M = M12 Waterproof outlet | ||||||||||

C3 | C3 = GX12 three cores aviation connector | ||||||||||

C4 | C1 = GX12 four cores aviation connector | ||||||||||

| H | H = M12 four cores aviation connector | ||||||||||

G | G= G1/2 | Pressure connection | |||||||||

| M | M = M20*1.5 | ||||||||||

1.0 | 1.0 = 1m | Cable length | |||||||||

2.0 | 2.0 = 2m | ||||||||||

3.0 | 3.0 = 3m | ||||||||||

LFT2700 | 0-60 | A4 | B | 1.0 | D1 | G | 1.0 | Example of Select | |||

Utilizzo del sensore a membrana a filo 316L, anti-intasamento, facile da pulire

Può misurare direttamente la pressione dei liquidi viscosi

Adotta la tecnologia ASIC, la tecnologia di compensazione digitale

Eccellente resistenza alla corrosione e all'usura

Connessione filettata per una facile installazione

Working with LEFOO

Different from another kind of diaphragm pressure transducer, Pressure Transducer Sensor LFT2700 is perfectly applied with the following equipment.LEFOO is a premier provider of metal diaphragms pressure transducers around the world. We are pleased to provide top quality diaphragm pressure transducer for:

Static liquid and fluid pressure monitoring;

Glue dispenser;

Food industries;

Pharmaceutical Industries;

Pulp and paper industries;

Wastewater processing;

Petrochemical industries.

Commercial manufacturing and production

Pressure levels and fluctuations are registered through the deformation of a diaphragm and attached silicon sensing core. The displacement of the diaphragm and core is proportionally converted into electrical current. That electrical signal is analyzed to determine accurate pressure measurements.

Diaphragms for pressure transducers can be composed of either metal or non-metal materials. Non-metal diaphragms are durable but tend to be less elastic than metal diaphragms. This makes them less desirable for applications that require precise measurements with low flow volume.

Metal diaphragms are circular plates composed of thin, flexible metal that exhibit deformation when under pressure. Diaphragms are used for both sealing and pressure transference. Diaphragm seals prevent fluid from leaking into other parts of the system while simultaneously preventing contamination of the fluid itself. Within a pressure sensor, diaphragms isolate the system and transfer the effects of pressure changes to the gauges, where the changes are converted into electrical current for analysis.

Metal diaphragms can be specially tailored to meet the needs of a wide range of industries and applications. There are two primary metal diaphragm designs: High-Sensitivity Low-Pressure (HSLP) and Low-Sensitivity High-Pressure (LSHP).

HSLP diaphragms are used for applications that require the diaphragm to operate with a great deal of flexibility under low-pressure conditions. They are more frequently used than their LSHP counterparts and are particularly useful for low-pressure applications that require a high degree of precision, such as food production and pharmaceutical manufacturing.

LSHP diaphragms must be more rigid and capable of retaining their shape and position in high-pressure applications. Their durability makes LHSP diaphragms valuable as protective barriers in high-pressure equipment. They can also be particularly useful for the conversion of pressure displacement into electronic signals. LHSP diaphragms are often designed to open at precise pressures, making them useful for applications that require highly accurate pressure measurements. Pressure-based medical equipment and systems that operate in extreme environments also benefit from the use of LHSP diaphragms.

We use two highly specialized tooling methods to manufacture quality metal diaphragms. The method used depends greatly on the intended thickness of the component and expected production volume.

For prototyping, sampling, and lower production volumes of less than 50,000 annually, metal-to-rubber tooling is appropriate for diaphragms with a thickness greater than 0.0015 inches. This process is less expensive than other tooling methods and ideal for swift small-scale production of highly accurate components.

Metal-to-metal tooling is ideal for production volumes that exceed 50,000 components annually, and for diaphragms with a thickness less than 0.0015 inches. This type of tooling can be relied upon to produce highly accurate components within tight tolerances for burr height, part configuration, and durability.

Metal diaphragms are highly versatile and have a broad range of uses in mechanical and industrial equipment, medical devices, and pressure transducers. Common uses of metal diaphragms include:

Conversion of movement into electrical signals

Protective fluid barrier

Flexible membrane for fluid pumps

Protective barriers and failure points

Due to their combined durability and flexibility, metal diaphragms can endure repetitive cycling for millions of strokes and are capable of operating accurately in extreme environments where they may be exposed to broad temperature fluctuations, corrosive materials, and extreme pressure.

Our engineering and manufacturing capabilities are second to none and our highly trained staff is committed to the accurate production of reliable pressure transducers from the initial design through prototyping and final production. Our quick-change tooling allows us to produce a variety of products simultaneously for quick turnaround and reduced lead times.

We specialize in the analysis and design of pressure sensing solutions to meet the varied needs of our customers. Read more about us to learn about our commitment to innovative solutions.

For more information on our metal diaphragms pressure transducer and other quality pressure transducers, contact us today or request a quote.

inchiesta sui prodotti