Bassa vibrazione e bassa rumorosità, alimentazione a pressione autoadescante e stabile, la pompa booster a membrana LEFOO 115VAC RO è ideale per applicazioni di sistemi RO interni e sistemi di booster d'acqua fai-da-te. IlPompa booster a membranaPuò essere utilizzato fino a quando è collegato all'alimentatore municipale. Con i filtri di pretrattamento e la membrana RO, la pompa può produrre acqua pura che ha a mala gli inquinanti e gli odori che rendono l'acqua un gusto fresco. L'industria del trattamento RO è priva di sostanze inquinanti e ha un costo inferiore rispetto al settore dell'acqua in bottiglia.

Il produttore della pompa ROLEFOOSarà la soluzione one-stop per la tua attività.

Pompa

| Parameters of 115VAC RO Diaphragm Booster Pump | |||||||||||||

| Connection | 3/8"NPT 3/8NPT'O' 1/4" Top Female quick connector, 1/4" Side Female quick connector, 1/4" Male quick connector | ||||||||||||

| |||||||||||||

| Product Model | LFP5050W | LFP5075W | LFP5100W | LFP5150W | LFP5200W | LFP5300W | LFP5400W | LFP5500W | LFP5600W | ||||

| Voltage | 115VAC | ||||||||||||

| Inlet Pressure | 0.2MPa | ||||||||||||

| Boost Pressure | 0.5Mpa | 0.5Mpa | 0.7Mpa | 0.5Mpa | 0.7Mpa | ||||||||

| Work Current | ≤0.17A | ≤0.19A | ≤0.3A | ≤0.35A | ≤0.45A | ≤0.6A | ≤0.63A | ≤0.7A | ≤0.8A | ≤0.75A | ≤0.85A | ||

| Work Flow | ≥600ml/min | ≥750ml/min | ≥980ml/min | ≥1500ml/min | ≥1900ml/min | ≥2700ml/min | ≥2950ml/min | ≥3250ml/min | ≥2800ml/min | ≥3600ml/min | ≥3200ml/min | ||

| Open Flow | ≥1600ml/min | ≥1800ml/min | ≥2000ml/min | ≥2200ml/min | ≥2500ml/min | ≥3500ml/min | ≥4000ml/min | ≥4800ml/min | ≥5500ml/min | ||||

| Bypass Pressure | 0.8~1.05Mpa | ||||||||||||

| Max Current | ≤0.24A | ≤0.28A | ≤0.4A | ≤0.55A | ≤0.65A | ≤0.85A | ≤0.97A | ≤1.05A | |||||

| Certifications | NSF, FDA, CE, ROHS, UL, REACH, EU Food Grade, BPA Free | ||||||||||||

Overview: 115V AC RO Diaphragm Booster Pump equipped with strong impetus DC motor with low noise, low vibration. The wet parts comply with food-grade requirements with high-strength plastic and metal pressure components, and the materials of sealing parts are all imported. Whole process quality control in electrical, sealing and water producing.

Model: 115VAC50/60HZ, which is a fully enclosed permanent magnet DC motor with natural cooling mode;

Power Line: It is able to be matched 1 meter or random lengths for the three-core power cord 18AWG with length 350mm.

Working System: According to different working conditions, S1 work continuously but S3 work intermittently.

Configuration: When the shell temperature rises to 64℃, the motor will stop working until the shell temperature drops to 35℃because of the overtemperature protection system in it.

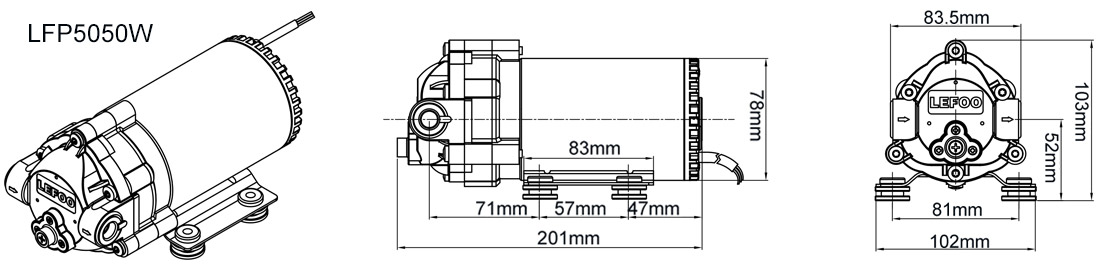

Bottom: Pls see the second diagram and the motor can be selected with or without the base.

Pump: Pls, see the third diagram. A Three-chamber diaphragm pump with a self-priming function and the head can choose different joints according to different plug requirements.

Typical Application: It is used for conveying or pressurizing drinking water or other liquids.

Pump: PA66(polyamide-66)

Picture: EPDM

Diaphragm: Santoprene (SP)

Faster: Stainless steel (SS)

Working Environmental Temperature: 5℃~40℃

Water Temperature: 5℃-38℃

Authentication Certificate: ROSH, CE, CQC, UL, NSF

Temperature rise curve: It is shown in figure 4 that the temperature rise curves of inlet 30PSI, outlet 70psi and 100psi at the corresponding ambient temperature of 31℃.

Flow and Current curve: Pls check the fifth chart and the characteristic curve is 30PSI for the water inlet.

Life: > 2000 hours (inlet 30PSI, outlet 70psi)

Noise: ≤35dB (A) (inlet 30PSI, outlet 70psi)

Conforme alla certificazione Rohs, CE, CQC

Struttura robusta in primo piano con parti per uso alimentare

Facile installazione, basso rumore e eccezionale controllo delle vibrazioni

Controllo di qualità dell'intero processo nella produzione di elettricità, sigillatura e acqua.

The diaphragm booster pump can be used in the following conditions:

RO water purifier pump, Aeroponics and hydroponics RO system, pressure adding pump

Water Treatment/RO

Carbonation Systems

Beverage/Coffee Systems

Water Vending, Dispensing

Hydroponics/Aeroponics

Misting Systems

Surface Sanitation

Humidification

HVAC Coil Cleaning

Medical Lab Water

Autoclave Systems

Endoscope Reprocessing/Chemical Boost

Dialysis Chemical Injection

Methanol & Water Injection

Sparkling Water Machine

Commercial Sparkling Water Machine

Commercial Carbonated Water Machine

Carbonation Systems

Commercial Water Dispenser

Water Dispensers

Soda Machine

RO Purifier

RO Water Dispenser

Water Coolers

Misting System

Teeth Cleaning Industry

inchiesta sui prodotti

22 Oct 2023

Passo nel futuro: Evolution of Stepper Motor pompe peristaltiche14 Oct 2023

Manipolazione dei fluidi innovativi: il viaggio della pompa peristaltica del motore passo-passo verso la precisione06 Oct 2023

Controllo di precisione e fluido: svolgendo la potenza della pompa peristaltica del motore passo-passo24 Sep 2023

Utilizzando l'innovazione: il futuro del trattamento delle acque con pompe per depuratori d'acqua English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Türkçe

Türkçe  Zulu

Zulu